A conversation with Carl Smith, CEO and president of Call2Recycle about the concept of the circular economy and its impact on battery recycling.

Because the circular economy advocates a broad view of environmental responsibility, it isn’t a one size fits all policy. Call2Recycle, North America’s first and largest consumer battery recycling organization, believes that the industry will need to develop policies that take into account the trade-off between economics, efficient resource utilization and waste. In the following interview, Carl Smith, CEO and president of Call2Recycle discusses the concept of the circular economy and its impact on battery recycling in North America. This piece was previously published in GreenBiz.com

Because the circular economy advocates a broad view of environmental responsibility, it isn’t a one size fits all policy. Call2Recycle, North America’s first and largest consumer battery recycling organization, believes that the industry will need to develop policies that take into account the trade-off between economics, efficient resource utilization and waste. In the following interview, Carl Smith, CEO and president of Call2Recycle discusses the concept of the circular economy and its impact on battery recycling in North America. This piece was previously published in GreenBiz.com

What does the circular economy mean to you?

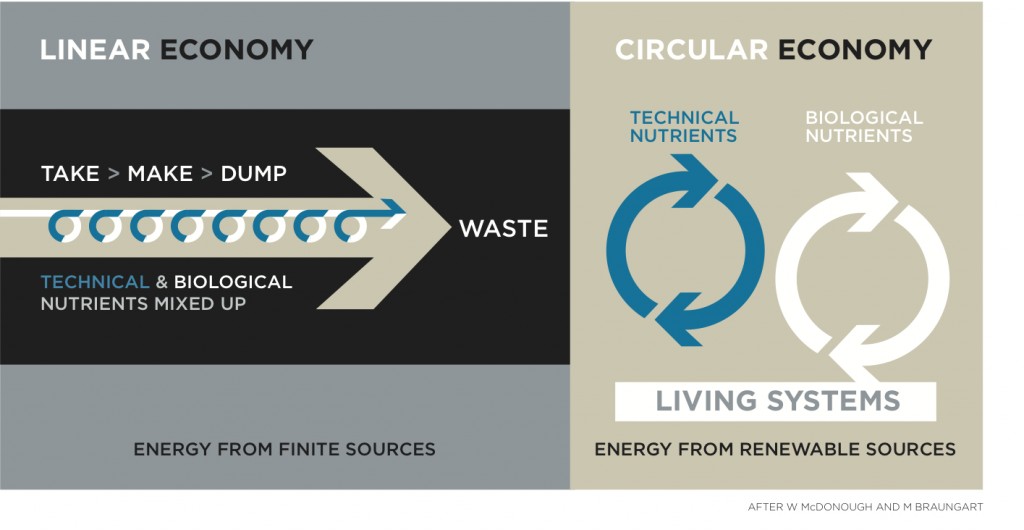

At its most basic level, the circular economy is about finding ways to create a virtuous circle of natural resources, everyday products and the waste that they generate that makes better use of resources. It involves leveraging a number of different strategies in waste management to keep materials from products in a loop of continuous use whenever possible while minimizing the environmental impact.

In what ways has Call2Recycle been involved in issues around the circular economy?

The battery recycling industry operates under a series of piecemeal regulations from many different jurisdictions. Generally speaking, battery processing performance has been historically measured by a metric called recycling efficiency rate (RER), which is expressed as an output of a process as a percentage of the input. We have come to the conclusion that this metric is both too simplistic and could promote behavior that is not environmentally positive. It doesn’t take into account how the output of the process might be able to be further reused or recycled. We have begun looking further downstream and upstream at our broader environmental footprint of recycling. For example, we are assessing the carbon footprint of transporting the goods to the sorter/recycler and trying to minimize that distance. We are examining at the downstream processes of our processors to ensure we are keeping recycled materials in an active process of re-use where they can be used again and again to create new products.

How have your views changed on the issue over time?

For two decades, we have operated as if recycling was our end goal as prescribed in state regulations. We paid attention to what happened to batteries through a single cycle of manufacturing, use and recycling. We made sure that the recycled materials were being used to make secondary products. We didn’t look much beyond that to what happened after a battery went through a single recycling process.

The circular economy advocates a longer term view. Let me give you an example. Zinc oxide is a byproduct of the alkaline battery recycling process that is sold on the commodities market. Zinc has value in so many different products. In the past, we made sure our recycled zinc was sold to make new products. Now we are asking different questions. How much recycled zinc vs. virgin zinc is used in these products? Can we increase how much recycled zinc is used versus virgin zinc? How can we ensure that all the zinc we recycle is in a cycle of use, recycle, reuse, and not reach a place where its reuse ends, such as when used as an additive to fertilizer. That is the dilemma of the circular economy. You may optimize the recovery zinc through a particular recycling process but if it is used to make a product that can no longer be reused or recycled, then you’ve fallen short of the goals of a circular economy. You may ‘win’ short term by delivering a higher recycling efficiency but you’ve lost the opportunity to have materials such as zinc become part of a bigger lifecycle. That’s the heart of the circular economy.

What are the most important obstacles you see in business fully embracing the circular economy?

One of the biggest hurdles to the adoption of the circular economy is the lack of key metrics. There are no clear measurements or methodology that tell businesses if there is a better or worse way to handle materials. Without the ability to assess downstream processes, we are flying by the seat of pants. The European Union and the Ellen MacArthur Foundation are early proponents, but we need private sector leadership to help shape concepts into reality. For the circular economy to be successful, the private sector has to collectively share its collective information and benchmark some metrics.

What kind of metrics are you referring to?

For the idea of the circular economy to gain traction in the mainstream, we need good metrics that truly capture the concept. For example, to what extent is an indicator of the amount of materials diverted from the landfill a good measurement? How does that take into account waste to energy as an appropriate alternative, particularly for materials that are very difficult if not impossible to recycle? For example, in some cases disposing of materials in the landfill is less energy intensive than recycling. In that case, the optimal solution is disposal, but that counts against you in current metrics. Recycling efficiency rates can also be misleading. They measure a point in time to optimize what is recovered but don’t take into account if the recycled materials reach end of life in the next production cycle (as fertilizer) or are used in a product that downgrades its characteristics (think of recycled paper being used to make toilet paper). In the battery world, the optimal solution is for its recycled materials to be used to manufacture new batteries. It’s the most energy efficient and maximizes reuse of the recycled materials.

Image credit: Ellen MacArthur Foundation

What are the things Call2Recycle is doing to recognize the circular economy in your operations?

One action we are taking right now is overhauling our sorting and processing collection infrastructure. We are taking a more long-term view. We aren’t just looking at how efficient the companies are at the recycling process or how much is being recovered for continuous reuse. We are also looking at the extent their outputs are going back into the production of new batteries or similar products. We want to ensure our materials are being kept in the production lifecycle.

Who do you see as driving the circular economy?

What distinguishes the circular economy is that it relies on the private sector, not the government, to develop the restorative economic systems that keep materials in a constant loop of production. One exception is the state of Minnesota, which has adopted a very forward-looking waste policy. For example, they don’t think that recycling of alkaline batteries for use as fertilizer qualifies as recycling because it takes the batteries out of this circular highway.

What is the future for the circular economy?

The circular economy is now part of the environmental lexicon. But it’s complex; it’s not a one-size-fits-all policy. It moves the bar from recycling to development of waste policies that support new sustainability practices that take a long term view. The challenge will be that there are no absolutes regarding waste. Sometimes it is more energy efficient not to recycle. We have to marry end of life considerations against having the most positive impact on the environment. To do that, we must look at the many nuances within the big picture of the waste/energy hierarchy.

ShareMAR